Jiangmen Yilin Precision Manufacturing Co., Ltd

Customer-centric, create value for customers

Jiangmen Yilin was founded in 2006 and located in “China home town of overseas Chinese"-Xinhui district of Jiangmen city, specializes in providing precision brass faucet machining by OEM and ODM. Yilin`s factory occupied 7500 square meters and has 130 employees including 8 engineers and 10 technicians.

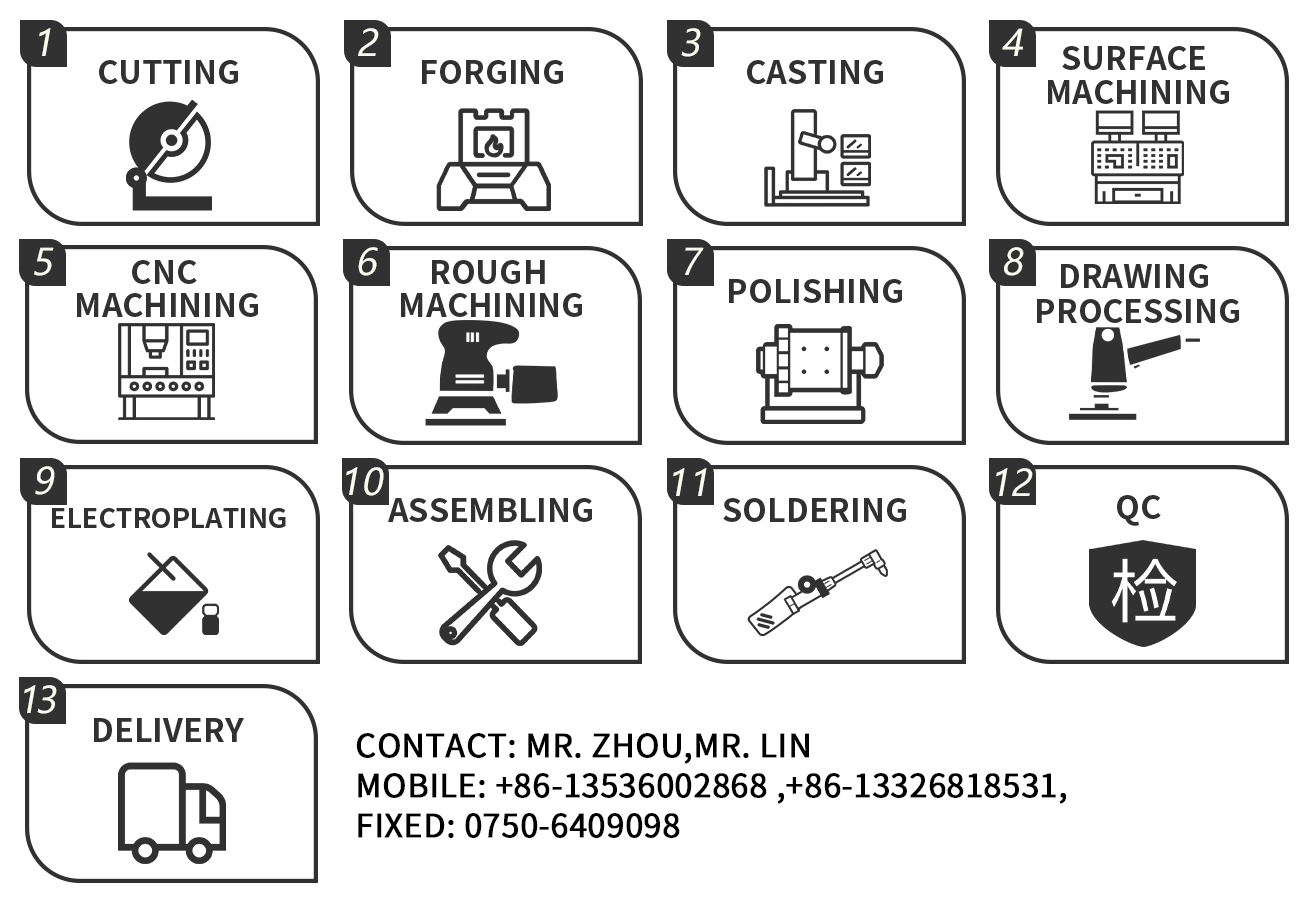

With More than 20 years` experience in this field, Yilin always keeps improving and extending, has the ability at machining process control, such as casting, forging, machining, stamping, surface polishing, plating, surface brushing and PVD vacuum coating etc. Yilin has 5 sets Four axis machining center, 80 sets of precision CNC lathes, 10 sets of Automatic hydraulic lathe and 2 sets of PVD coating equipment. And we also has Projector, torsion test machines, coating thickness test machines and salt spray test machines for making sure the stable quality. We will make various products based on the customers` requirements and market demands. About the Raw material we are using following raw materials: Low Lead Brass, No Lead Brass, CW724R, CW614N, CW617N, CW510L, CW511L, Hpb59-1 and DZR, CW602N etc.

Yilin is standing on “Taking the customers as the center, to create the values for customers" and becoming one of the excellent OEM suppliers for famous international sanitary ware manufactures.We would keep improving our management system and deeply implement quality system ISO9001:2015.

Warmly welcome domestic and oversea customers to visit our factory and raise your valuable comments to improve our managements. We will cooperate sincerely with you and develop together.

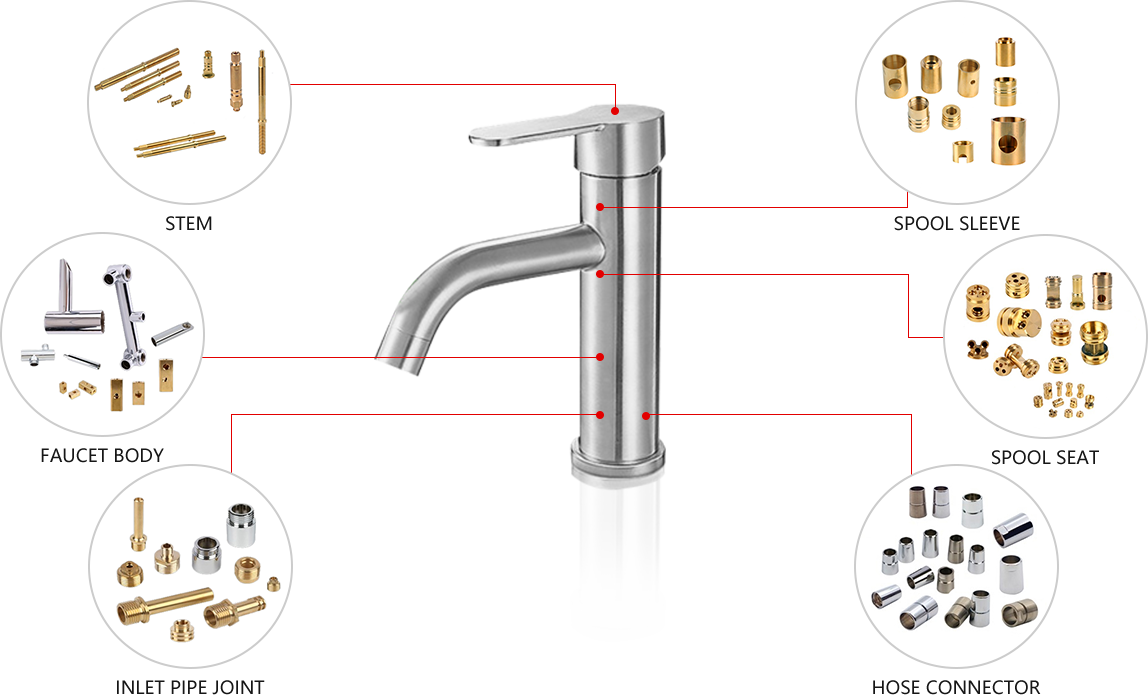

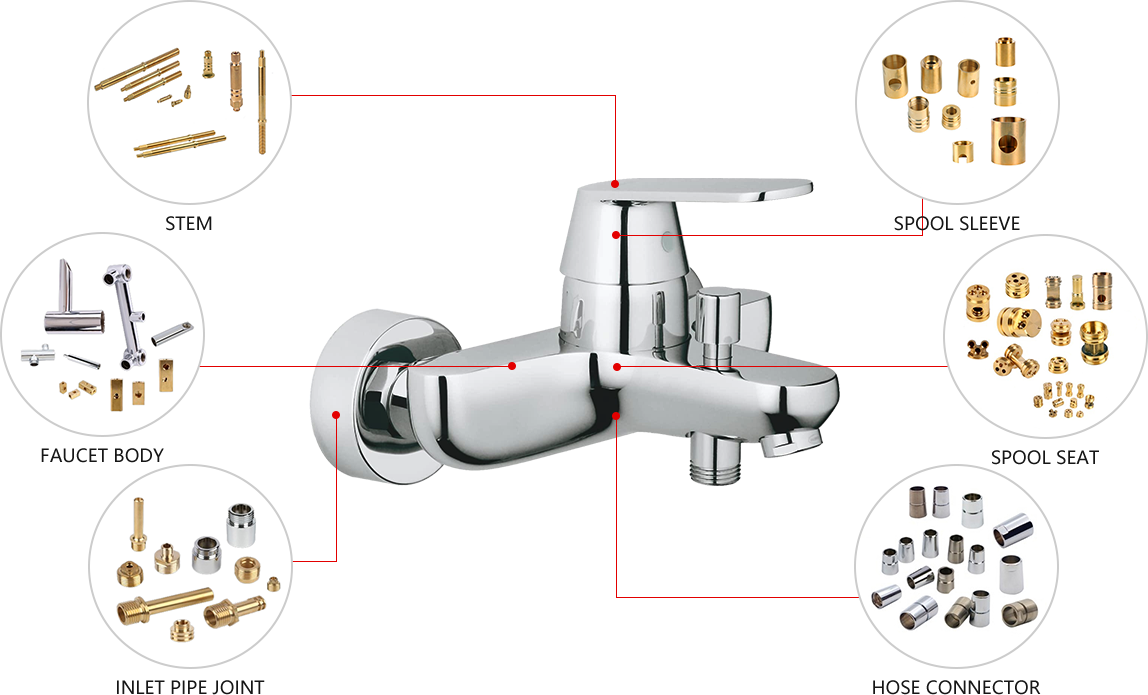

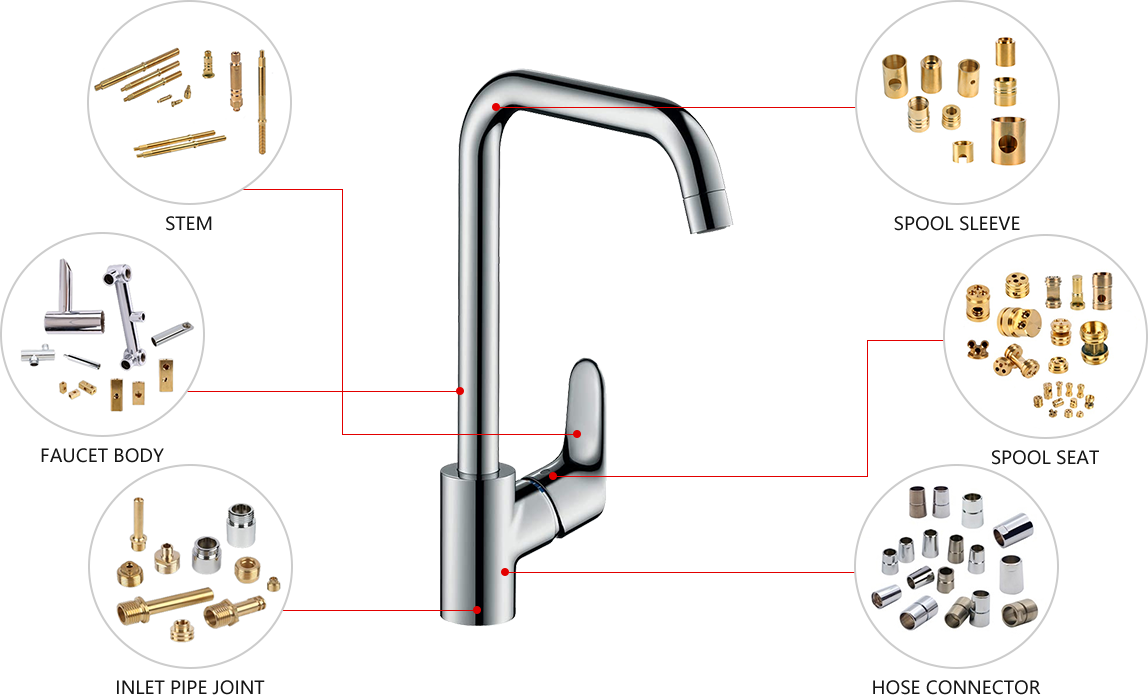

PRODUCT

Provide one-stop service

Four advantages of choosing Yilin

Complete equipment and perfect performance

Factory processing equipment has 10 sets of four-axis machining center, 80 CNC precision CNC lathes, 30 CNC precision vehicles, 15 large forging equipment. Quality testing equipment, spectrometers, hardness testers, roughness testers and other equipment and advanced testing instruments equipped with projectors, film thick testers to ensure quality stability.

Rich experience and strength casting

It is fully equipped with the processing and process control capabilities of copper forging, machining, stamping, surface polishing, electroplating, surface drawing and PVD vacuum coating. We communicate and confirm customer needs based on actual conditions.

Technological innovation of technical team

It has a 11-acre factory area and living area, our technical team: more than 150 employees, including 10 engineers, QC17. All teams cooperate to cooperate, strictly control the quality of controlled products.

Worry free after sales service

A strong after-sales team can provide customers with one-stop production services to ensure product quality. Online customer service quickly responds to customer needs and answers product questions.

Welcome to inquire:

+86-13536002868(Mr. Zhou)

+86-13326818531(Mr. Lin)

NEWS

ISH 2025 Concludes with Great Success – Yilin Participated in the Global Event

2025-04-18

The ISH 2025 trade fair successfully concluded on March 21, 2025, at Messe Frankfurt. With over 2,000 exhibitors and more than 160,000 visitors from 154 countries, the event reaffirmed its status as the world’s leading platform for HVAC and water technologies.Under the theme “Solutions for a Susta

Exhibition for YILIN

2022-11-22

What are the types of bathroom accessories?

2021-01-12

Appearance treatment of copper fittings

2021-01-12

What are the advantages and disadvantages of different materials of bathroom accessories?

2021-01-12

Bathroom copper accessories manufacturers teach you how to choose bathroom accessories

2021-01-12